CAD/CAM Dictionary

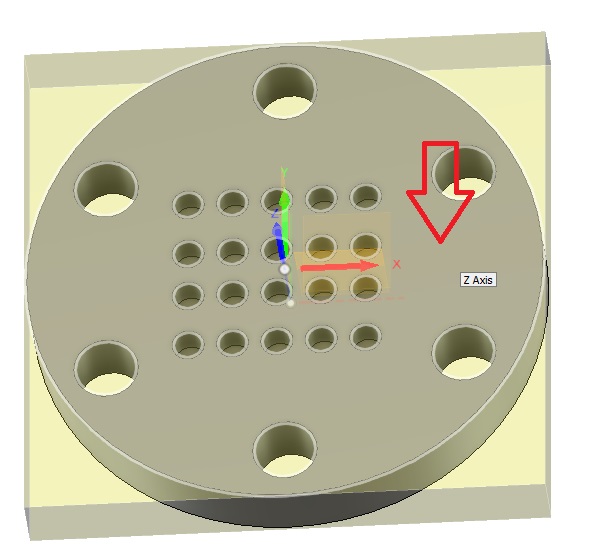

Axis: A spatial direction along which the path of motion. There are three primary axes, X, Y and Z. Each primary axis has a relative axis along that axis; A, B and C.

A-Axis: The axis of motion that revolves along the X-Axis.

B-Axis: The axis of motion that revolves along the Y-Axis.

Boolean– a 3d modeling function used to modify or create a solid body by combining, subtracting, or intersecting more than one body.

Boundary: a geometric parameter of constraint used to confine or exclude a toolpath.

Boundary Representation ( B-Rep) : a method used in solid modeling to define geometry that’s represented by edges, faces, and vertices.

CAD: Computer Aided Design; The use of computers to assist in the design process.

CAM: Computer Aided Manufacturing; The use of computers to assist in manufacturing.

CAD/CAM: Computer Aided Design and Computer Aided Manufacturing. See Digital Manuacturing

Cartesian Coordinates: A three dimensional system used to represent a position, location, or direction of motion in space.

C-Axis: The axis of motion that revolves along the Z-Axis.

Circular Interpolation– A toolpath that moves along a circular arc. Circular interpolation is defined by: an endpoint

- an endpoint

- a feed rate

- a center point or arc center

- a radius

- a direction of movement

Chamfer: an angle on the two intersecting edges of a part.

Closed Profile– a chain of geometry that connects together without any gaps.

0 an “o” shaper is closed, or a closed profile.

U a “u” is an example of an open profile.

Collision Detection: A CAD/CAM software feature that detects or predicts a collision of the tool and the part or stock being machined.

Constraints: Spatial parameters or boundaries that are used to define relationships within geometry. Constraints may be used to associate parametric or variational geometry within a CAD system.

Constructive Solids Geometry (CSG): a 3d modeling method using primitives to build more complex models and Boolean operations of add, subtract, and intersection.

Cutter Diameter Compensation (CDC) : A programming method used to alter a toolpath to compensate tool diameter wear.

Cutter Offset: The axial distance from the cutting tool center to the cutting tool diameter (Tool Radius).

Cycle: The sequence of operations and repeated processes that a CNC executes within a program. also see Cycle Time.

Double Geometry– Double geometry is a geometry that overlaps over other geometry in the same position. Example:. line segment overlapping another line segment. Two lines but appears as one line.

DWG: A 2d CAD drawing file format commonly used in Autocad.

DXF (Drawing Exchange Format): a common file format for 2d CAD drawings and geometry used to transfer CAD data from one CAD system to another.

Interpolation: A CNC function where generated data points control movement to a given coordinate position.

Lathe Driven Tools – (independent driven tools / mill tools)

Axial Tools- tools parallel with the workpiece

Radial Tools – tools that are perpendicular to the workpiece

Linear Interpolation: A CNC function where generated data points control movement to a given coordinate position to allow simultaneous motion to one or more axes in a linear path.

Loop: A programming method used for continuous repetitive operations where the operator will input the needed number of repetitive tasks.

Gap (profile gap) – a gap in a profile where the geometry chain doesn’t connect.

Operation: A set of machine sequences or toolpaths for a particular setup or side of a part. Each time a part is flipped over is a different operation.

Revolve Tool: Revolves a selected profile around a selected axis.

Toolpath: the path that a tool moves in order to cut or rapid into position to cut.

Translate: To move or shift an element or solid over.

Turning Profile: a contour or cross section of a lathe part. The profile rotates along the center of rotation (X0 or the z-axis).

Also See:

Fusion 360 Tutorial-Circular Pattern-Rectangular Pattern